In the world of engineering and mechanics, the term “shaft” is often used to describe a fundamental component that plays a crucial role in transmitting power and motion. Whether it’s in a car, a wind turbine, or a simple hand tool, understanding what a shaft is and how it functions can provide valuable insights into the workings of many mechanical systems.

What is a Shaft?

A shaft is a rotating machine element designed to transmit power and motion between various components within a system. It typically has a circular or annular cross-section and is extruded up to a certain length, giving it a cylindrical appearance. Mounting structures at the ends allow for assembly with other mechanical components via appropriate fasteners.

Shafts are essential in most mechanical systems because they enable the transfer of rotational force from one part of a machine to another. This makes them vital in applications ranging from automotive engines to industrial machinery. Despite their seemingly simple design, shafts are complex components that require a strong conceptual understanding of engineering disciplines such as design, heat transfer, stress analysis, and manufacturing.

Types of Shafts

There are several types of shafts, each designed for specific applications and load conditions:

Transmission Shaft

Transmission shafts are used to transfer power between components in mechanical systems. These systems include engines, gearboxes, drive assemblies, and more. A transmission shaft transfers rotary motion and torque from one part of a machine to another. For example, in automotive gearboxes, multiple transmission shafts transfer input power from the power source to different devices, allowing for the conversion of input torques and speeds to desired values.

Machine Shaft

Machine shafts are general-purpose mechanical shafts that serve as integral structural and functional components of a machine. They may have design features like keyways, threads, or splines depending on their application. For instance, an engine shaft such as a crankshaft or camshaft includes features like counterweights, cams, and cooling channels to perform additional functions beyond just transmitting torque.

Flexible Shaft

Flexible shafts are useful in applications where rigid shafts are impractical. Their flexibility comes from coiled or braided metal wires, allowing them to bend and twist without losing the ability to transmit rotational motion. These shafts are commonly used in medical devices, robotics, and other specialized machinery.

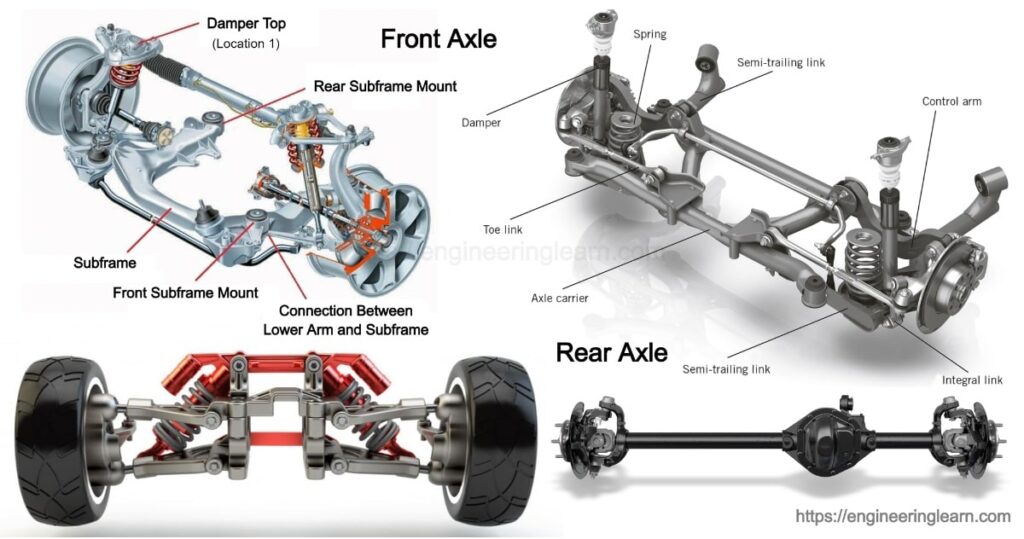

Axle

Axles are automotive shafts that support and drive critical components like wheels. They transmit power from the engine to the wheels while also bearing the vehicle’s weight. Due to this, axles are subject to intense loading conditions, requiring them to be highly durable and resistant to bending forces.

Propeller Shaft

Propeller shafts are special-purpose transmission shafts designed to transmit rotational power to propellers, primarily in marine applications such as ships. They connect the motor to a propeller, whose blades generate thrust to push the body through a fluid (typically air or water). Propeller shafts require high torsional and bending strengths, as well as corrosion resistance.

Stub Shaft

Stub shafts are short shafts that primarily serve as interfacing devices in mechanical devices rather than load-bearing components. They are commonly used in gearboxes, where they extend slightly from a larger shaft or housing. Their free, cantilever end features splines or keyways to attach other coupling components for power transmission.

Common Materials for Manufacturing Shafts

The choice of material for manufacturing shafts depends on the design goals, application, and budget. Some common materials include:

- Carbon Steel: High strength and hardness, moderate fatigue resistance, excellent machinability.

- Stainless Steel: High tensile and fatigue strength, excellent corrosion resistance, moderate machinability.

- Aluminum: Lightweight, excellent corrosion resistance, easy to machine.

- Titanium: Very high strength-to-weight ratio, excellent corrosion resistance, hard to cut.

- Plastics: Lightweight but low strength, available in different colors, low to moderate cost.

- Wood: Very lightweight, low strength, susceptible to degradation.

- Composites: High strength-to-weight ratio, excellent stress resistance, very expensive.

Types of Stresses in Mechanical Shafts

Mechanical shafts undergo various types of stresses during operation, including:

Shear Stress

Shear stress develops due to torsional loads, which try to slide one part of the cross-section in one direction and the other in the opposite direction. The shear stress formula is:

$$ \tau = \frac{T \cdot r}{J} $$

Where:

– $ \tau $ = Shear stress (N/m²)

– $ T $ = Torque (Nm)

– $ r $ = Distance of forcing point from the center (m)

– $ J $ = Polar moment of inertia (m⁴)

Bending Stress

Bending stresses occur when a shaft bends under loads and gravity. The bending stress formula is:

$$ \sigma_{\text{bending}} = \frac{M \cdot y}{I} $$

Where:

– $ \sigma_{\text{bending}} $ = Bending stress (N/m²)

– $ M $ = Bending moment (N·m)

– $ y $ = Distance of the forcing point from the neutral axis (m)

– $ I $ = Moment of inertia (m⁴)

Axial Stress

Axial stress occurs when a shaft carries axial loads, either in the form of pulling (tensile) or pushing (compressive). The axial stress formula is:

$$ \sigma_{\text{axial}} = \frac{F}{A} $$

Where:

– $ \sigma_{\text{axial}} $ = Axial stress (N/m²)

– $ F $ = Axial force (N)

– $ A $ = Cross-sectional area of the shaft (m²)

Thermal Stress

Thermal stress arises from temperature changes causing expansion or contraction. The thermal stress formula is:

$$ \sigma_{\text{thermal}} = E \cdot \alpha \cdot \Delta T $$

Where:

– $ \sigma_{\text{thermal}} $ = Thermal stress (N/m²)

– $ E $ = Young’s modulus of the material (N/m²)

– $ \alpha $ = Coefficient of thermal expansion (1/°C)

– $ \Delta T $ = Change in temperature (°C)

Fatigue Stress

Fatigue stress occurs due to cyclic loading, leading to material weakening over time. Engineers use concepts like stress endurance limits, mean stress in a loading cycle, and number of cycles to failure (S-N curves) to evaluate fatigue resistance.

Vibration

Vibration is an unavoidable occurrence in mechanical devices. Sources include mass imbalance, mounting devices, and external forces. Engineers must design shafts to avoid resonance, ensuring fundamental frequencies fall outside the operating frequency range.

Design and Manufacturing Considerations for Custom Shafts

To ensure optimal performance, there are several design and manufacturing considerations for custom shafts:

Dimensioning

Incorrect dimensions can lead to assembly issues and premature failure. Proper dimensioning ensures the shaft fits with other components and can withstand the loads in its operating environment.

Tolerancing

Defining the correct tolerances in engineering drawings is critical for effective assembly. Improper tolerancing can lead to component failures, low mechanical efficiency, and high maintenance costs.

Form

The form of a mechanical shaft refers to qualities like cylindricity, coaxiality, and runout. A shaft must be as close as possible to a perfect cylinder to avoid uneven mass distribution and damage to components.

Surface Finish

Surface finish affects frictional forces between the shaft and mating components. A smooth surface finish aids with fatigue resistance, micro-stress concentrations, and thermal conductivity.

Balancing

Mass balancing is critical for high-speed applications. An imbalanced shaft adds extra loads to load-bearing components, decreases mechanical efficiency, and increases the chances of failure.

Applications of Mechanical Shafts

Mechanical shafts are present in a wide variety of machinery, covering nearly every industry from home appliances to aviation. Some common applications include:

- Automotive Industry: Engines, gearboxes, axles, and propeller shafts.

- Industrial Machinery: Conveyor systems, pumps, and turbines.

- Aerospace: Aircraft engines, landing gear, and control systems.

- Medical Devices: Surgical tools, robotic arms, and imaging equipment.

- Consumer Electronics: Electric motors, fans, and printers.

Conclusion

Understanding what a shaft is and how it functions is essential in the field of engineering and mechanics. From transmitting power and motion to withstanding various types of stresses, shafts play a critical role in the operation of many mechanical systems. Whether you’re designing a new machine or simply curious about how things work, knowing the basics of shafts can provide valuable insights into the inner workings of the world around us.

Stay updated with the latest news on mechanical engineering and innovation by exploring today’s headlines.

More Stories

US Trending News: What Is Sarah Oil and Why Is It Trending Now?

How to Use the Scholastic Book Fair E-Wallet: A Complete Guide for 2024

US Trending News: How to Use an Old Version of Scrabble Cheat for Classic Gameplay